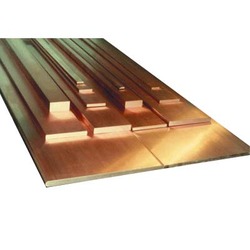

Copper busbars manufacturer

Quick turnaround at competitive prices

Electropak has advanced copper busbars manufacturing equipment, which offers exceptionally high levels of delivery performance, ensuring your project is finished within budget and on time. Our busbar manufacturing process enables us to provide this copper busbar service to all customers throughout Lancashire and the UK.

At Electropak, we take pride in being the leading provider of high-quality copper busbars, revolutionising electrical connections in diverse industries. With our cutting-edge technology, extensive expertise, and unwavering commitment to excellence, we offer you the most efficient and reliable solutions for your power distribution needs.

- We provide busbar production to the highest standards and specifications

- All our busbar manufacturing equipment is high-tech and provided in-house

- Our equipment allows for advanced design techniques

- We are ISO 9001 & AS9100 Rev D approved

- Electropak deliver every busbar project on time, every time

- Date of delivery is always 100%

- We can provide busbar manufacturing for one-off requirements and much larger production volumes

- We are capable of completing complex shapes/ edge-bending capability to reduce copper usage and assembly time

- Assembly of earth bars and insulators can be carried out if required

- In-house electroplating facility: silver, tin and zinc

- Epoxy powder-coated insulation is carried out in-house at our paint facility

- Sleeving supplied and fitted if required.

You can supply your own drawings or allow our experienced technical team to help to optimise the cost and design before busbar manufacture. We can supply a full range of copper, aluminium and cuponal sizes and can process up to 16mm thick by 200mm wide in lengths of up to four metres on our advanced CNC hole-cut machines. We can also carry out the process for larger sections using Electropak’s CNC and conventional machining techniques. Our AS9100 rev D approval enables Electropak to manufacture precision aerospace busbars. Our rates are competitive and we promise you won’t find a more reputable company to carry out the work on your project other than Electropak. With years of experience in busbar manufacturing place your trust in us to deliver on time and on budget.

We understand that each project is unique. Our team of skilled engineers works closely with you to design tailor-made busbars that precisely match your specifications. From size and shape to coating and plating options, we’ve got you covered. Our copper busbars find applications in various industries, including energy, telecommunications, transportation, and more. From switchgear and power distribution units to renewable energy solutions, our busbars are versatile enough to accommodate a wide range of applications. Time is crucial in any project, and we value your time as much as you do. Our efficient manufacturing processes and robust supply chain ensure that your custom-made copper busbars are delivered promptly, so you can keep your projects on track.

To speak to an experienced Electropak Copper Busbar specialist, please telephone 01772 251444, or use our contact us form. We will be happy to help with your project enquiry.